Taipei American School · 2023

Motorized Go-Kart

Project Overview

The Motorized go kart was developed as part of the Mechanical Engineering course at Taipei American School. The objective was to create a go kart from scratch, developing mechanical, circuit, and machine shop skills. The project combined mechanical design, electric motor integration, and machine shop fabrication including CNC waterjet to produce a functional vehicle that could compete in time trials.

Design Process

The development process followed a rapid prototyping approach, as there was limited time to build a complex system. When designing, weight was most carefully considered, as at the power of the motors we used, the power to weight ratios would be the greatest differentiators in performance. We were also provided with an example kart to base our designs on. A basic rectangular frame was desgined first, then the sides and gearbox. The designs were deliberately kept simpler to allow for greater room for error when manufacturing and assembling the system.

- Powertrain: Two electric motors, configured to supply torque to two wheels of the same side.

- Steering: Given parallel AWD configuration, steering was tank-like, allowing for great rotational maneuverability.

- Electronics Integration: RC Receiver and Transmitter to control the car remotely or while seated.

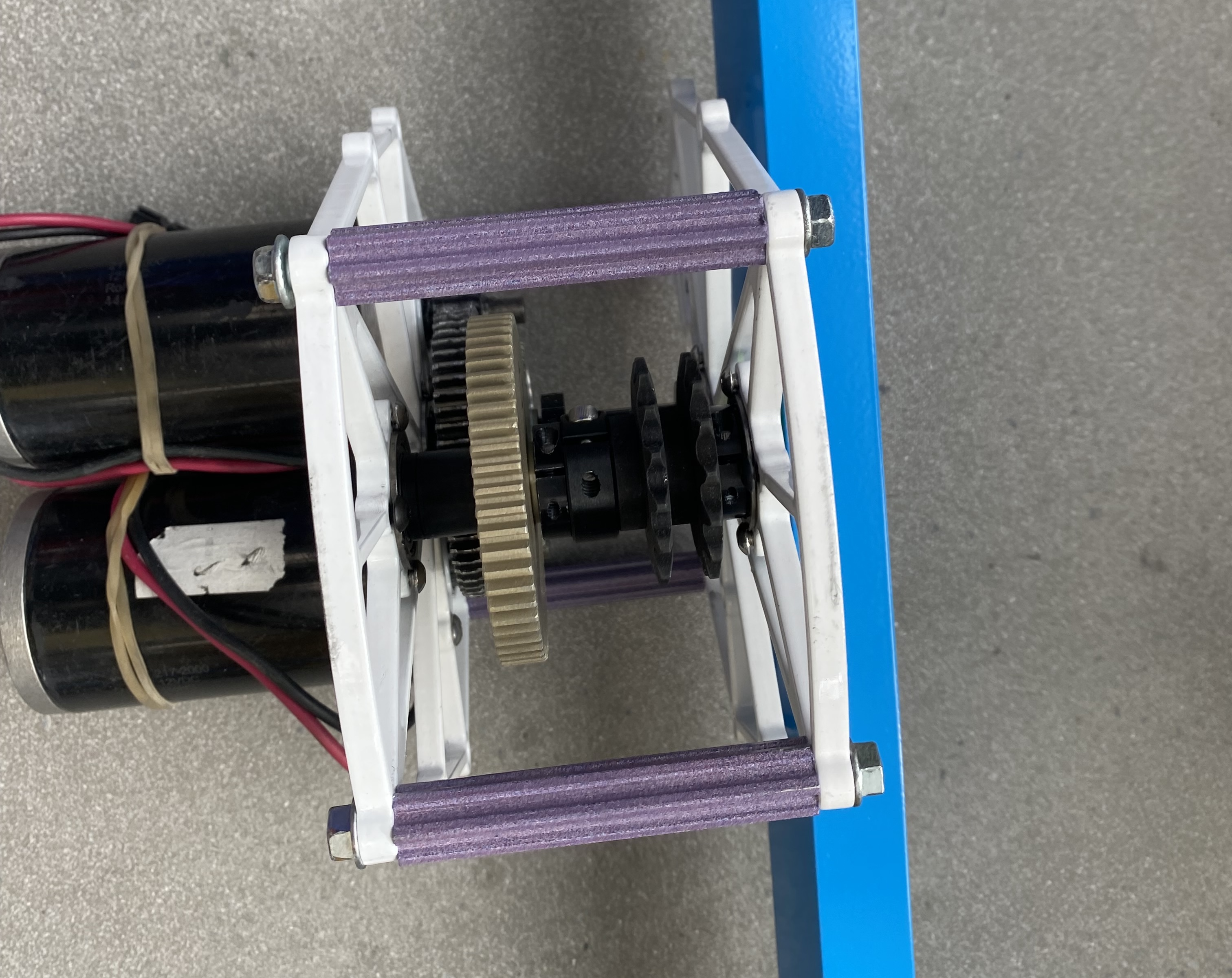

The gearbox of the example kart provided.

Manufacturing and Machining

The kart was built entirely from scratch using Taipei American School's Techcube machine shop tools. Different tools were used for different purposes.

Preview of cutout of go kart component being created via waterjet CNC, out of aluminum.

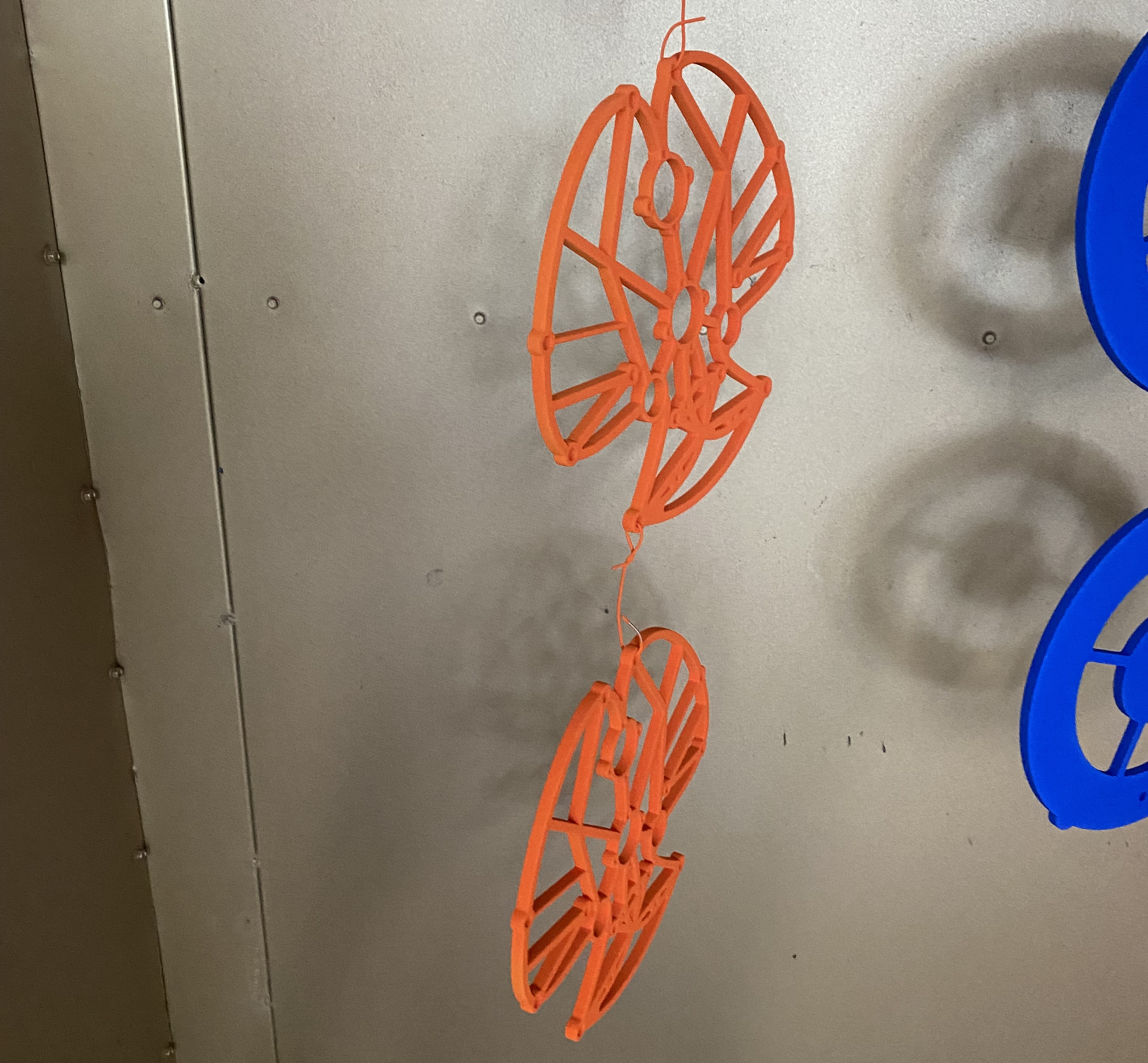

Go kart component hanging to dry after being powder coated.

- Materials: Wood, aluminum, nuts, bolts, rivets.

- Machining: Band saw, CNC waterjet, knee mill.

- Refinement: Belt sander, disk sander, soldering, riveting, nut and bolt assembly.

- Finishing Touches: Powder coat painting, soldering.

Trial Results

The final prototype was the quickest of all karts in the time trial test, where a series of obstactles had to be driven around precisely, then having to brake quickly and deliver a payload to a designated position, then come back. The final prototype also acheived the greatest top speed in a straight line trial, making it the highest performing of all concurrent and past carts with its speed and trial time. These results were due to the initial design considerations of maximizing power relative to weight by taking weight reducing measures whenever possible. They were also because tank-like steering was used, allowing for quick rotation.

- Trial Time: 18.81 seconds.

- Top Speed: 36 kilometers per hour.

- Total Weight: ~70 kg including driver.

- System Reliability: Zero cases of subsystem failure.

Future Improvements

- Improve efficiency of drivetrain, requiring less frequent recharges.

- Change drivetrain for more diverse applications, beyond given trial. Tank treads worked in this case, but are generally more limited.

- Create more complex chassis that is even more weight efficient. A rectangle is good for simplicity, but not entirely optimal.

- Integrate on-board steering, not relying on RC, for more fine-tuned control over the vehicle, and to escape inherent occasional RC unreliablity.

Conclusion

This project demonstrated how a complex, well-tuned system can come to life under rapid protyping principles. Having completed all trials and tests with flying color, this motorized go-kart serves as a great foundation that can be refined for more advanced motorsports applications.