Current Project · September 2025

UAV Optimization

Project Overview

This ongoing project focuses on the optimization of a Unmanned Aerial Vehicle (UAV) through advanced engineering techniques. By pairing Computational Fluid Dynamics (CFD), Finite Element Analysis (FEA), and additive manufacturing, the goal is to create a drone frame that maximizes thrust, stability, and aerodynamic efficiency while minimizing weight.

Process Overview

The development follows a rigorous engineering workflow, moving from theoretical simulation to physical prototyping. The process involves iterative design cycles where simulation data directly informs the physical geometry of the drone frame.

- Design & Simulation: Using ANSYS for topology optimization and CFD to determine the optimal material distribution.

- Material Selection: Integrating simulation results to guide the choice of materials and manufacturing methods.

- Prototyping: Utilizing Fused Deposition Modeling (FDM) for rapid prototyping of the optimized frame.

- Assembly & Testing: Sourcing international components and performing in-house assembly and flight testing.

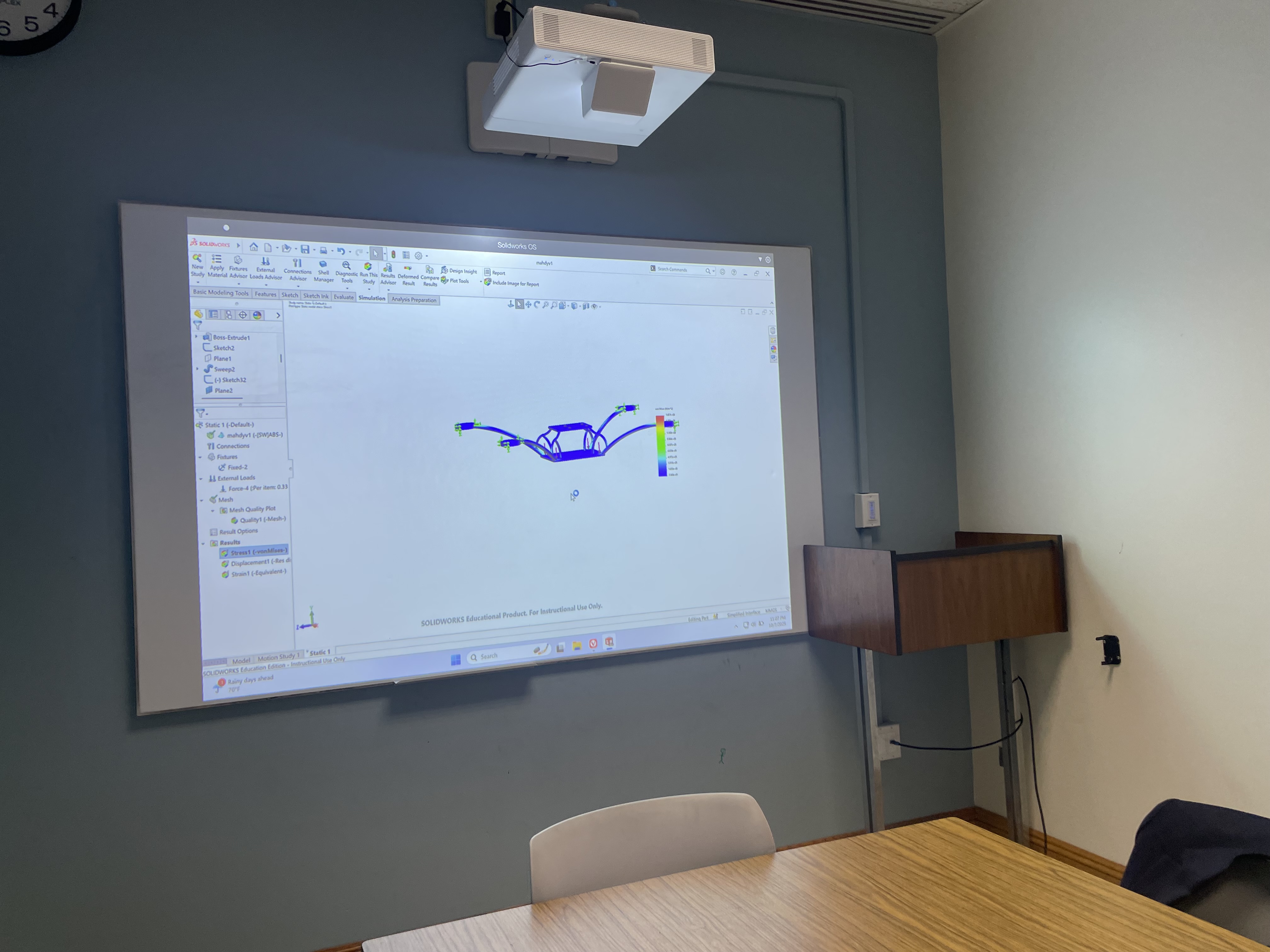

Design & Simulation

The design phase relies heavily on computer-aided engineering. Initial designs are subjected to FEA to identify stress concentrations and topology optimization to remove unnecessary material.

Early CAD sketches and design concepts for the drone frame.

Topology optimization results showing optimal material distribution.

Fabrication & Assembly

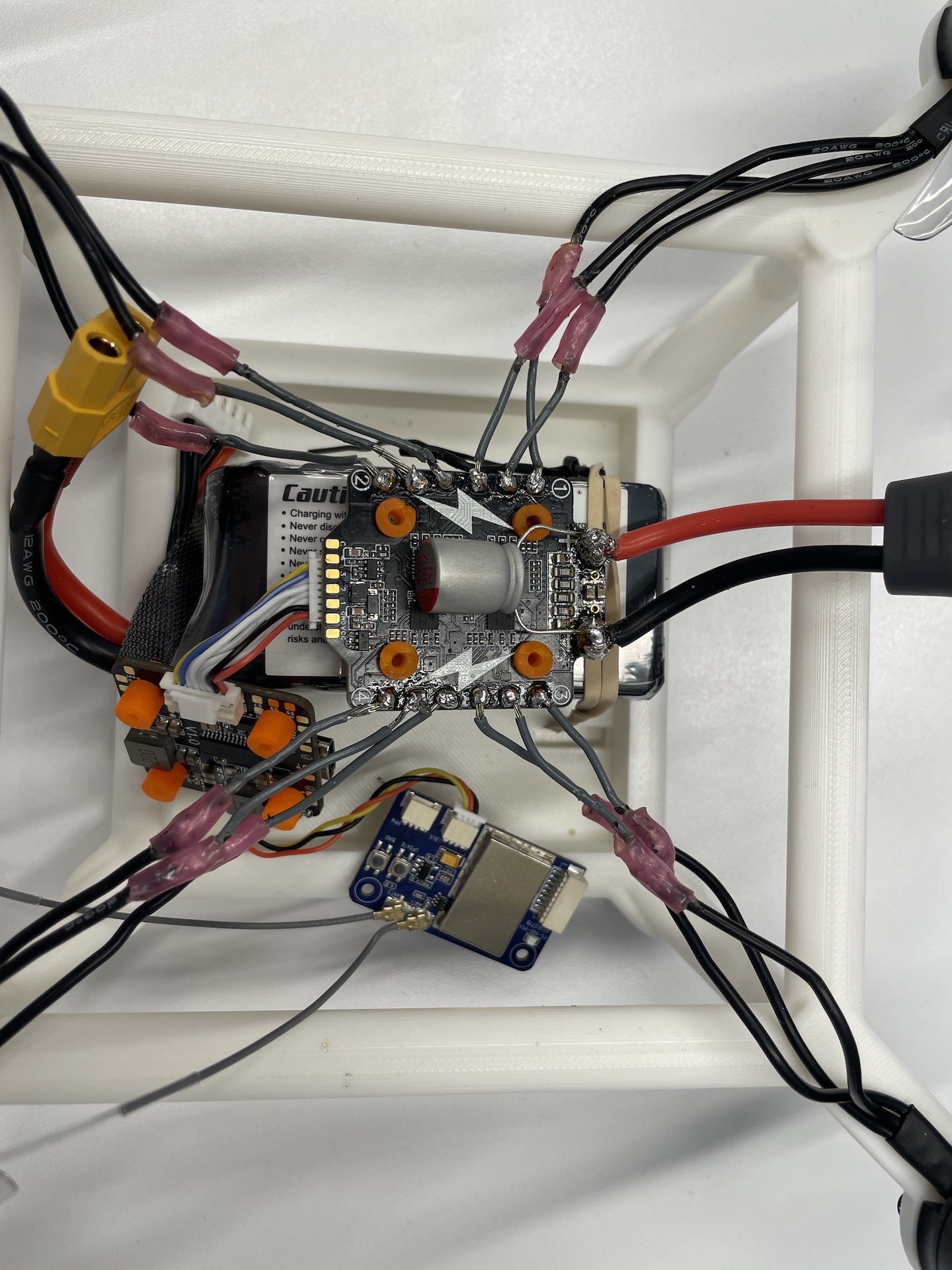

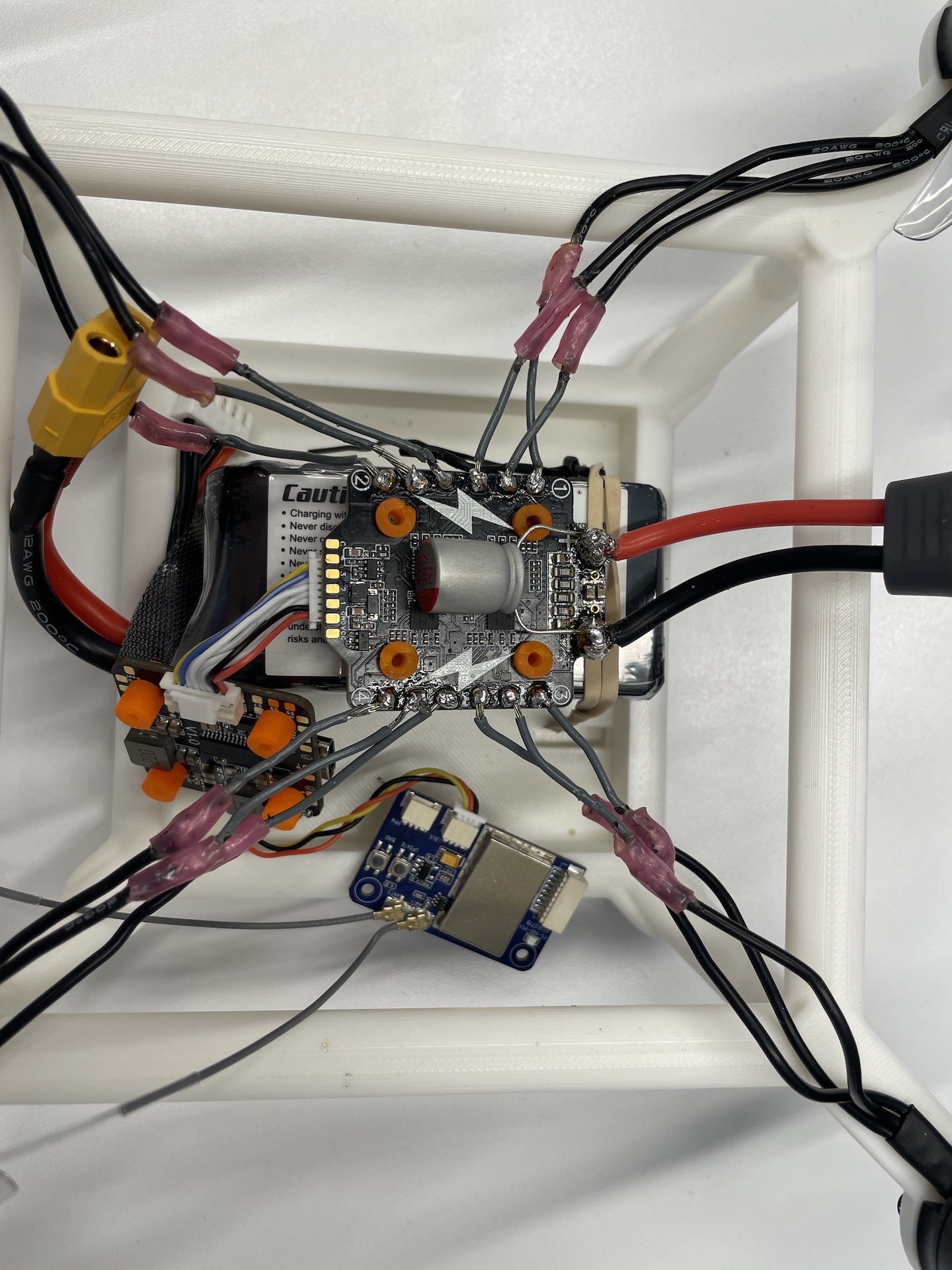

Once the design is validated, the frame is manufactured using 3D printing. Components are sourced and assembled, requiring precise soldering and wiring.

First iteration of the 3D printed frame.

Sourced components ready for assembly.

Completed wiring and soldering of the electronic speed controllers.